Factory Manufactures The Filter

Factory Manufactures The Filter We are a research and development and large-scale production of automobile filter enterprises, strong technical force, has a professional R & D team and perfect testing equipment, manufacturing high-quality and affordable products is our goal, has been tracking the development and changes of the market, constantly introduce new products, the use of advanced product software, and the implementation of network information management, after years of continuous efforts,

Send Inquiry

Product Description

Factory Manufactures The Filter

The manufacturing process for filters typically involves the following steps:

-

Design and Development: Engineers and designers work together to develop filter designs that meet specific filtration requirements and performance criteria. This stage may involve computer-aided design (CAD) software and simulation tools to optimize filter performance.

-

Material Selection: The appropriate filter media and materials are selected based on the filtration needs and environmental conditions the filters will encounter. Common filter media include fiberglass, synthetic fibers, activated carbon, and other specialized materials.

-

Cutting and Assembly: The selected filter media is cut and shaped into the desired dimensions. The media layers may be pleated or assembled in specific configurations to increase surface area and filtration efficiency. Frames and casings made of plastic, metal, or other materials are also assembled to provide structural support.

-

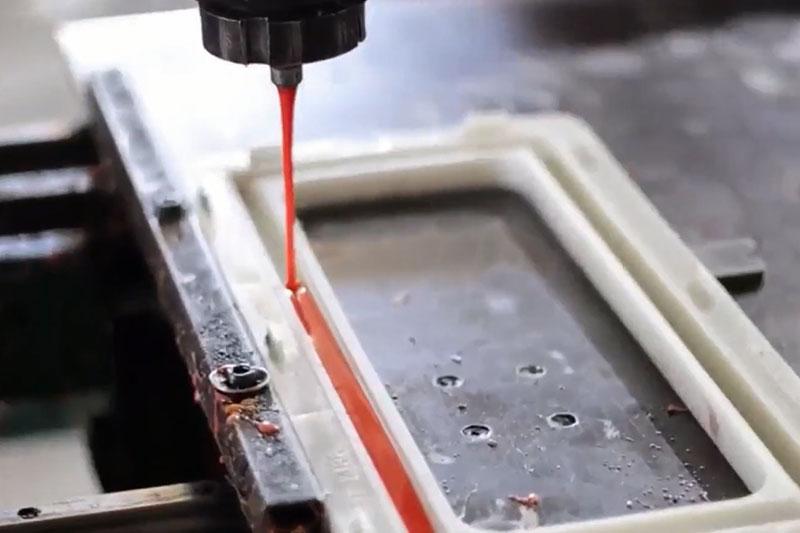

Adhesive Application: Adhesives are applied to bond the filter media and frames together securely. The adhesive must be compatible with the filter media and provide a durable and reliable bond.

-

Quality Control: Quality control procedures are implemented throughout the manufacturing process to ensure that each filter meets the required specifications. This may include visual inspections, dimensional measurements, and performance testing to verify filtration efficiency and airflow resistance.

-

Packaging and Distribution: Once the filters have passed quality control checks, they are packaged for shipment. Proper packaging ensures that the filters remain protected during transportation and storage. The filters are then distributed to wholesalers, retailers, or directly to customers, depending on the manufacturer's distribution channels.

In addition to manufacturing standard filters, some factories may offer customization options to meet specific customer needs. This can include custom sizes, shapes, filtration ratings, and special features tailored to unique applications.